Our technology

Technology

Agritech

Unlike other alternative energies such as solar, wind and hydro, Agernomics’ bio-energy products are portable and allow end-users to use their existing infrastructure. The Agernomics platform is highly flexible and scalable, and has been designed to form a ‘virtuous economic circle’ not only in terms of efficient production and distribution of bioenergy with accompanying decarbonization, but also in terms of poverty alleviation, land rehabilitation and power generation in developing regions which has attracted growing government and corporate ESG interest.

Technology

Torrefaction Technologies

Agernomics uses its proprietary, conventional torrefaction technology to turn BioVoltz™ biomass into a high-grade solid biofuel (“bio-coal”) to replace coal for the generation of power and/or heat.

Agernomics’s conventional torrefaction technology has been proved and demonstrated at industrial scale and BioVoltz™ Bio-Coal black pellets have been successfully tested by independent laboratories.

Technology

BioVoltz™ Black Pellets

Torrefied BioVoltz black pellets are carbon neutral and

have a high energy density. BioVoltz black pellets

surpass other biomass fuels and can even replace

fossil coal 1:1 for industrial usage.

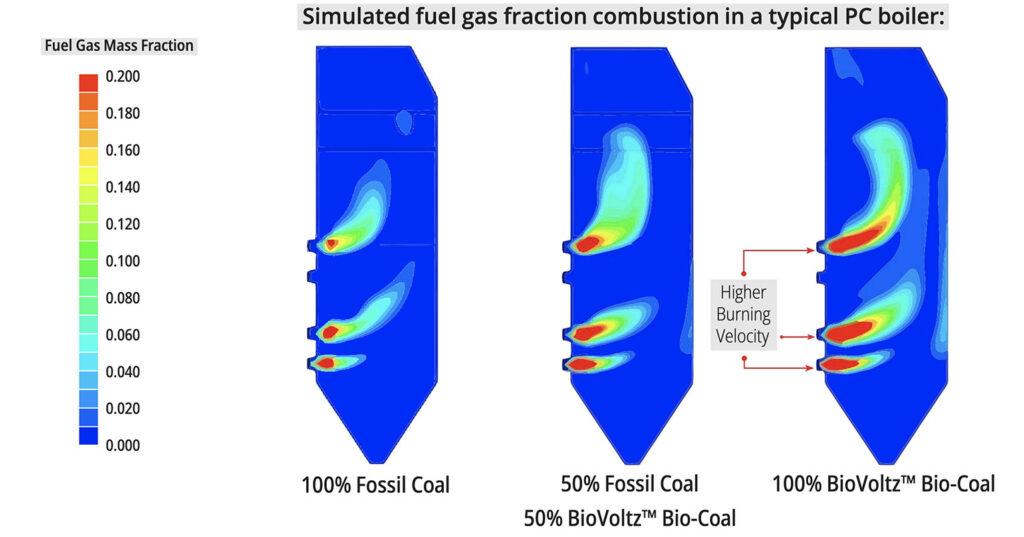

Burning velocity

Pulverised Coal Boiler computational tests show biomass bio–coal >300% more

burning velocity and heat transfer efficiency compared to fossil coa

Technology

Microwave torrefaction

Agernomics Biotech believes that constant research & development will provide the foundation for improvements in its feedstock, processing efficiencies and end products to ensure that it remains at the forefront of the bio-energy industry and generates additional future income streams.

Its research team has been collaborating with Taiwan’s prestigious Industrial Technology Research Institute for over a decade on Phase Array Matrix (“PAM”) variable frequency microwave system to develop a next-generation, energy-efficient torrefaction technology for biomass.

After testing the system on biomass in a lab scale pilot, a large-scale PAM system was built and successfully used to torrefy biomass. Agernomics is now working with ITRI to build an industrial production system for the torrefaction of BioVoltz™ feedstock in Bali Indonesia at the G20 Summit in October 2022 together with its proprietary plasma gasification technology for the production of SAF and D5 biodiesel.

Technology

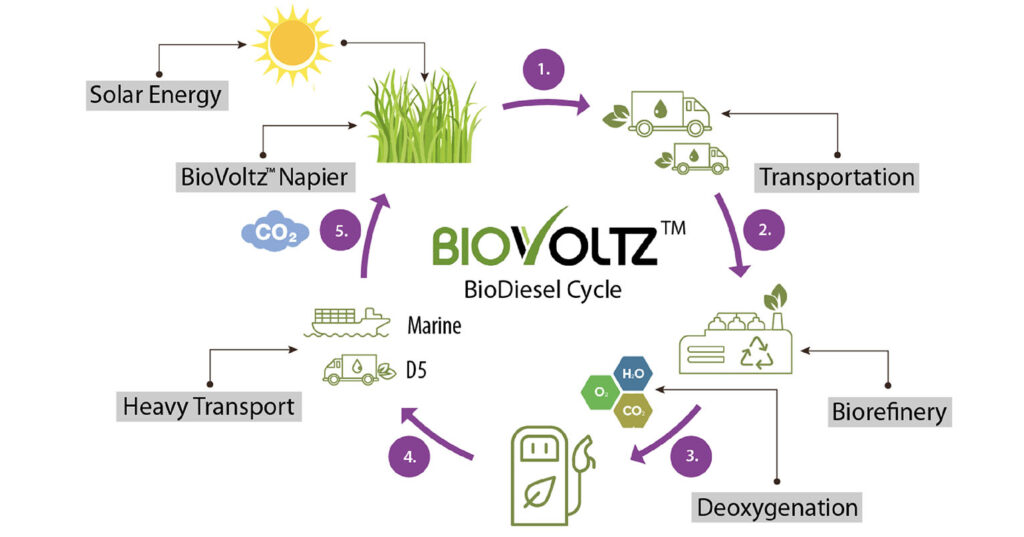

Biodiesel

Technology

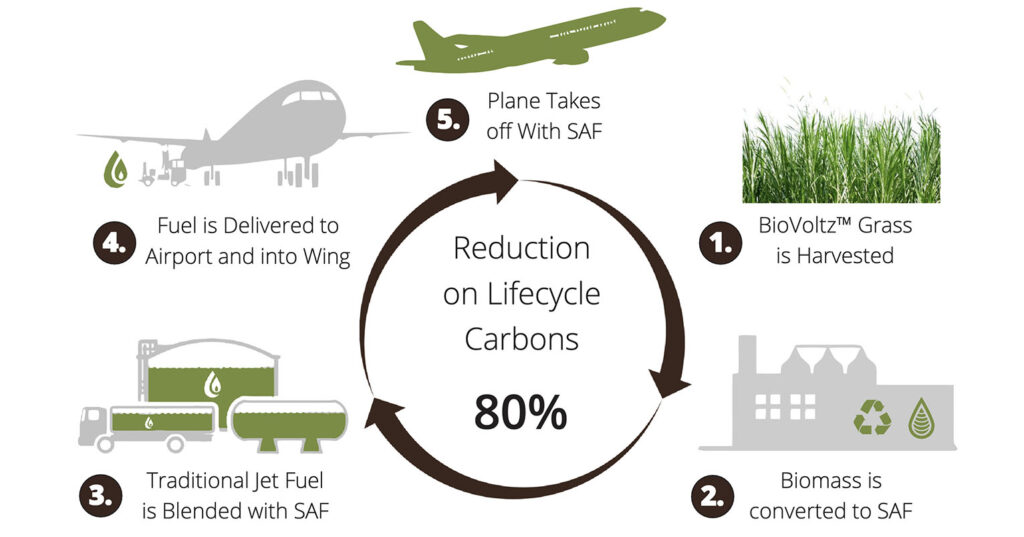

SAF

Technology

Plasma pyrolyis/gasification

Agernomics’ proprietary plasma pyrolysis system is a unique, cost-effective, and virtually emissions-free technology that is superior to other mainstream methods of biomass treatment.

Feedstock can be processed homogenously or simultaneously, minimizing preprocessing, staging, sorting and management costs.

Technology

Thermal Plasma W2E Technology

Agernomics Thermal Plasma Waste–to–Energy Technology (ATPT) uses the heat

generated by plasma electrodes in an oxygen starved (pyrolytic) environment

to first pull apart (dissociate) the molecules of organic waste and thenreform

the dissociated elements into synthesis gas (“syngas”). This process isreferred

to as plasma gasification and leaves reduced non–toxic emissions.

ATPT can process landfill, medical and hazardous waste to extract commodity

recyclables and convert carbon–based materials into fuels. The ATPT process is a

unique, cost–effective, and virtually emissions–free technology that is superior to

other mainstream methods of waste treatment. Agernomics ATPT results in 100%

waste diversion of ALL feedstocks thereby eliminating any landfill requirements and / or further processing, while producing zero greenhouse gas emissions.

Technology

Research & development

Information will be added shortly.